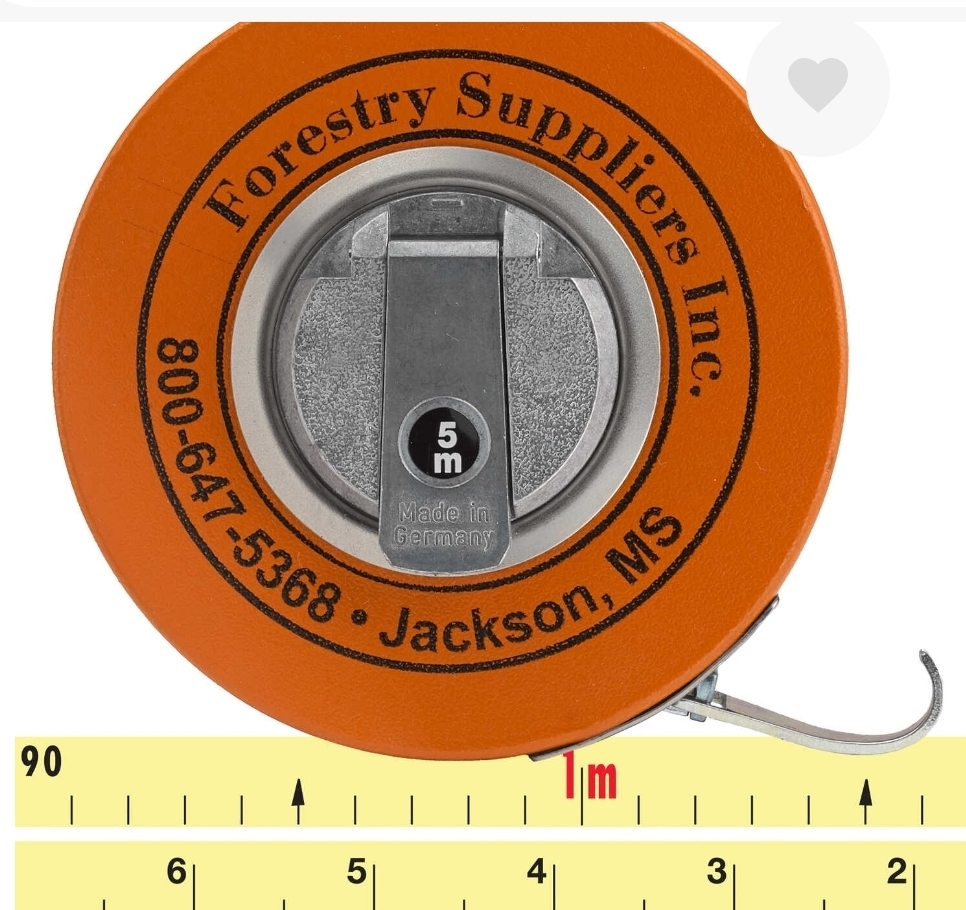

You can buy these with a calibration certificate for like $70, but I skipped the cert. Should be the same quality, cost me $16. I chose the version with the superior units of measurement.

Conspiracy theory: they have loose tolerances at the assembly line. They are all checked if they meet the certification criteria. The ones that do gets the paper and the stamp and the ones that don’t go in the other bin and are sold without a cert.

That’s a possibility but assuming they all come off the same assembly line then I feel like they should be relatively consistent. My colleague has a tape measure that is “class 1”, which means it has at most 1.1mm deviation over 10m. I’m hoping to compare the two, we’ll see.

Edit: that actually seems less likely now that I think about it. The tape measures that are certified are certified by NIST, which is not cheap. If Starrett knew that many of them would not meet the spec then I don’t think they would attempt to certify all of them. If a business wants to pay the money to have certified tape measures than I think they probably want some traceability for the precision of their measurements.

They could measure themselves and just send the ones that meet the criteria for certification by someone else. Anyway it’s a funny tinfoil theory and they are probably all good quality.

Yeah good point. I’ve been growing my collection of tinfoil hats lately.

Believe it or not, but this is how CPUs and other microchips are handled. For a specific architecture, the chip is tested and depending on how many cores are working and how well it performs, it will be sold as say i3, i5 or i7 (in case of Intel).

This sounds correct.

I don’t know about the accuracy. Those inches look awefully small. 😁

They’re centi-inches

You joke but there are actually architects scale tape measures out there that have tenths of a foot and tenths and hundreths of an inch rather than the normal fractional scale.

Be warned if one is around, you might be about to have a really bad day.

Are those the funky triangular ones? My dad had one for some reason.

The triangular ones are sales used for drawing and measuring plans in standard scales. There are engineering scales and Architectural scales, which are very different.

The Engineering scales use scales of 1:10, 1:20, 1:30, 1:40, 1:50, and 1:60 scales, and are usually used for drawing at a scale like “1 inch= 50 feet”. They’re generally used for civil engineering, so the plans show a larger area.

Architectural scales have scales based on fractional inches and are weirder, with units that are 1.5", 1", 1/2", 3/8", 3/16", and 1/8". They’re used for larger scale drawing like buildings rather than the site-level drawing from the engineers.

I’ve seen that! I don’t think the bulk justifies the 6 sides unless you take nerd cred into account.

Seriously, they are very useful if you are doing something relevant like drawing a scale plan for a house addition you want to build and have to submit a set of blueprints to the building inspector. Done that a few times. After the nerd cred, you pick up the framing hammer and start the real work.

In metric it’s easy to divide by 20 or 50. Still, the drawing board my father used as a civil engineer only had double-sided ones (1:1 and 1:50).

So, decifeet, deci-inches and centi-inches.

That’s actually an engineering scale. No standard Architectural scales use decimal inches.

Or diameter tape

I’m just now realising British tape measures are probably pretty unique in that they typically come with one side metric, one side imperial

Every other tape measure I have has both. I bought this one with the intention of achieving as much precision as reasonably possibly. If I’m going for precision I’m going metric. Also in almost every other situation I use metric. Not a single fucking tape measure at Home Depot has metric anymore.

If you want precision you should use a ruler.

Sure, but the longest one I have is 12 inches, which is good enough for most of the stuff I measure but I’ve been making big stuff for my new client.

You need a [60" Johnson ](http://www.johnson.com/ Level J60 60" Aluminum Straight Edge | Johnson Level & Tool Mfg Company https://share.google/HQbAKGtEWP4jL6tjz)

Not that uncommon. In Canada you can buy metric, imperial, or dual-unit tapes. People who use them routinely at work will buy single-unit tapes so they don’t have to check which side they’re on. Dual units are handy for us mortals who use them infrequently and need both.

These are annoying as hell. You can’t pick a system and then just go because you always end up measuring with both sides of the tape depending on how things are oriented, so now you have one side that isn’t useful.

Just get a metric tape when you need a metric tape and vice versa. The dual tapes are for housewives.

Oh don’t get me wrong, I’d prefer a simply metric one, it’s just I think there’s still a generally* generational divide here between metric and imperial, so your standard hardware shop seems to stock the dual measurement kind.

*Interestingly around my age (mid/early-millennial) some people use imperial for measuring their height & similar measurements and metric for most other things. I’m not sure how far back and forward that behaviour goes

You don’t want to go down that road in Canada. We’ve had the metric system for 50 years now and the way we measure things around here is schizophrenic.

There’s 3 systems; imperial, metric, and time. And you might measure the same thing in all three depending on the magnitude of the measurement. Very short distances are in mm and cm, a little more is in inches and feet (height, carpentry), then miles because our rural road grid is laid out in miles, then kilometers because the highway is all signposted in metric, then minutes and hours because the distance between towns and cities isn’t relevant when you account for weather.

“Barrhead is about 2 hours north, when you get to the end of town, go 20km until you get to a 4 ways stop. Go 4 miles north and turn left. About 200 meters from the corner will be a driveway, turn in there and about 40 feet in you’ll want to park and walk from there.”

That hurts my brain. I only speak one language, too though, so my brain prolly just isn’t very plastic

Trust me, most of the people in Barrhead only speak one language, or less. :-)

I don’t find that the accuracy really matters as long as you’re using the same tape measure and not switching between multiple different ones.

Hultafors Talmeter is what I use for woodworking.

That’s fair. Generally yes, it doesn’t matter most of the time. I worked in metrology for a couple years and appreciate having accurate measuring devices. I have other tape measures that look and feel better to use but I wanted something that I can be confident is accurate. Maybe I should have paid for the one with the calibration cert.

Starrett is a decent brand for tape measures!

I work in a calibration lab and we see a fair amount of tape measures come in. It consists of us using a high accuracy machine to measure the incriments. I have a Harbor Freight tape that is super accurate somehow. Lol.

You can also use a combination of Gage blocks that measure 6" to make sure that when you push/pull the tape, that it measures the same. When you do the pull part, hang it from the blocks. The push parts require something to butt the block and tape end up against to make sure they are square (like another block or something straight).

Got one of these a while back but it broke. Though even before that I still preferred my cheap, auto-locking Stanley tapes. And I have several Starrett combo squares and calipers, so I’m aware of the brand reputation, but I believe these are manufactured overseas and they just slap the Starrett name on them.

The Starrett doesn’t seem particularly rugged, we’ll see how it goes. My tools generally don’t get damaged much, I don’t do any serious construction or anything, I usually work in a lab environment.

Slap! And the name goes on. That’s an efficient industrial manufacturing production process, right there.

Yah, I use a few Starett instruments in the shop, they’re pretty nice. But these aren’t anything special, I have one. It’s just a tape measure and not even particularly well built. I don’t think it’ll survive many drops, not like my Fat Max tape. But then again, it won’t leave a dent in the floor like the Stanley.

Now you can check your bin of cheapo tapes and chuck the ones that are off.

Also, you need to get a micro-point pencil for marking cuts, or a laser if you can afford it. That blob of graphite you’ve been using ain’t gonna cut it anymore.

He needs a CMM now to go with his gucci tape measure.

Coordinate-measuring machine

Its a machine that uses a very small probe to measure things with precision

I used to work in the alignments department at an aerospace company and we used something called a laser tracker made by Faro. It could measure down to ten-thousandths (0.0001) of an inch in X, Y, and Z up to 60 feet away. It’s able to measure how much a 3 foot thick concrete floor flexes due to the gravitational pull of the moon.

Thats some crazy shit!!

A marking knife! When I bought one it changed my woodworking, I’m only off a little now.

Yeah… I use 0.9mm lead in my drafting pencil. I tried 0.3mm once but it breaks if you breathe on it too hard.

I’ve never been impressed with laser alignment of tools; red laser diodes tend to put out a line that to my eyes looks about 1/8" wide.

My miter saw tries to be clever and cheap about it and has a white LED positioned behind the blade so that it casts the blade’s shadow on the work. Kinda wish they hadn’t tried that because, with a miter saw, I can just lower the blade onto the work, line it up with the mark on my work, and then cut. Feels like putting holographic sights on an axe.

I use a FastCap ProCarpenter tape measure. It has the lord’s own metric, nasty incheses for when we can’t avoids thems, a reusable writing surface, a pencil sharpener, and a tape lock button/brake for quick measurements and to help keep the tape from snapping at you when it retracts. It’s also very accurate. I only wish they made a wide one like the FatMax.

I have one, it’s OK. Not much of a stickout, it flops at about 6 or 8’. It’s certainly not made like their machining instruments.

I have one of these exactly, and while I trust its measurement the case feels cheap and flimsy.

Yeah you’re not wrong.

Let’s see the tip of the band please!

If it’s the same loosy-goosy metal catch that’s sort of dangles on a rivet, you’re always going to be 2-3 mm wrong regardless of the precision of the tape itself.Edit: I now know that didnt know how to use a measuring tape and I feel enlightened, relieved and somewhat embarrassed - thanks all for helping learn something new.

That loosy-goosy end is there for a reason: it gives the right reading when hooked on the outside of an object and is pulled out, but also when put on the inside (of a corner, for instance) and is pushed in.

If yours has a fixed one then it’s less accurate than any other one with a loose end.

It’s loose for a reason. It moves back and forth exactly the thickness of the clip itself.